As a leader in the field of aluminum alloys, Zhenhan Alloy’s 7075 aluminum tubes have been widely used in many industries due to their high strength, high hardness, high toughness and excellent corrosion resistance. The following is a detailed inventory of the application fields of 7075 aluminum tubes.

1. Aerospace field

In the field of aerospace, 7075 aluminum tubes play a vital role. It is often used to manufacture aircraft structural parts, such as fuselages, wings, landing gear and other key components. These components need to withstand high-intensity loads and have strict requirements on weight. The high strength and lightweight characteristics of 7075 aluminum tubes can not only effectively reduce the weight of the aircraft and improve fuel economy, but also maintain the integrity and safety of the structure in extreme environments. Its high strength and excellent fatigue resistance ensure the stable operation of aircraft in high-speed flight and complex environments.

2. Automobile industry

The automobile industry is also an important application field for 7075 aluminum tubes. In high-performance cars and racing cars, 7075 aluminum tubes are used to manufacture high-load components such as frames, suspension systems, and engine brackets. Its light weight and high strength characteristics help improve the overall performance of the vehicle, while reducing the weight of the vehicle body, improving fuel efficiency and acceleration performance. In addition, 7075 aluminum tubes are often used to manufacture automobile wheels, further improving the handling and safety of the vehicle.

3. Shipbuilding and marine engineering

In the field of shipbuilding and marine engineering, 7075 aluminum tubes are favored for their excellent corrosion resistance. It is often used to manufacture hull structural parts, marine equipment and other components. In the marine environment, 7075 aluminum tubes can maintain their performance and stability for a long time, ensuring the safety and durability of the hull. At the same time, its high strength and high toughness also meet the operation requirements of ships in harsh sea conditions.

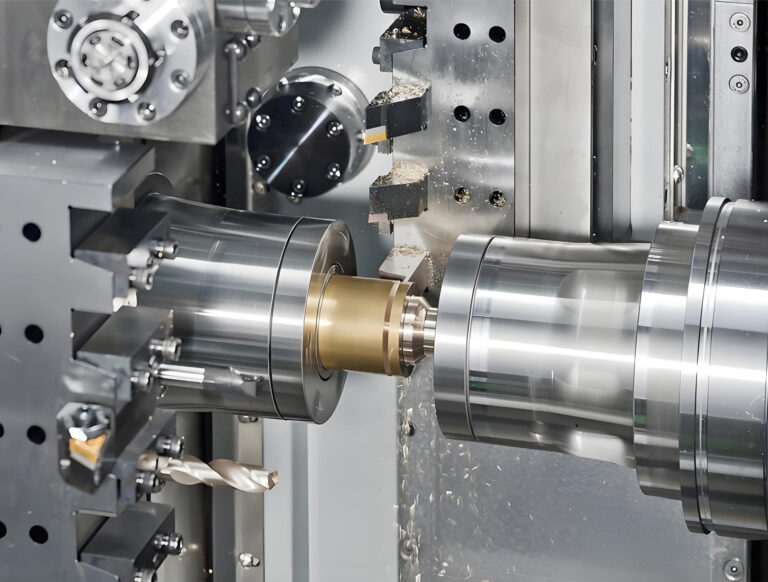

4. Mechanical manufacturing

In the field of mechanical manufacturing, 7075 aluminum tubes are widely used due to their good processing and forming properties. It can be used to manufacture various mechanical parts, such as bearings, gears, connecting rods, etc. These parts need to withstand greater stress and load during mechanical operation, and the high strength and high hardness characteristics of 7075 aluminum tubes can ensure that they have better load-bearing capacity and durability.

5. Sports equipment

In the field of sports equipment manufacturing, 7075 aluminum tube also performs well. It is used to manufacture high-performance bicycle frames, golf club heads, baseball bats and other sports equipment. These equipment need to withstand high-intensity impact and repeated stress during use, and the excellent performance of 7075 aluminum tube can ensure that they maintain stable performance and long-term durability during use.

6. Other fields

In addition to the above fields, 7075 aluminum tube is also widely used in mold processing, electronic equipment, building structures and other fields. Its good mechanical properties, corrosion resistance and machinability make it play an important role in these fields.

The 7075 aluminum tube produced by Zhenhan Alloy occupies an important position in many industries with its excellent performance and wide application fields. Whether it is aerospace, automotive industry, shipbuilding, or machinery manufacturing, 7075 aluminum tube has provided strong support for the development of all walks of life with its unique advantages.