Aluminum profile

Brand: 6061, 6063, 6082

Characteristics: Can be strengthened by heat treatment, has moderate plasticity in annealing, quenching, and hot state, has good spot welding performance, and tends to form intergranular cracks when using gas welding and argon arc welding

Application scope: Aircraft structures (skins, skeletons, ribs, frames, etc.), aircraft, ships, transportation, rivets, missile components, truck hubs, propeller components, etc

Special services: nationwide sales, 0 yuan sample collection, 0 yuan home delivery, customization based on drawings and samples available

Share to:

Product Details

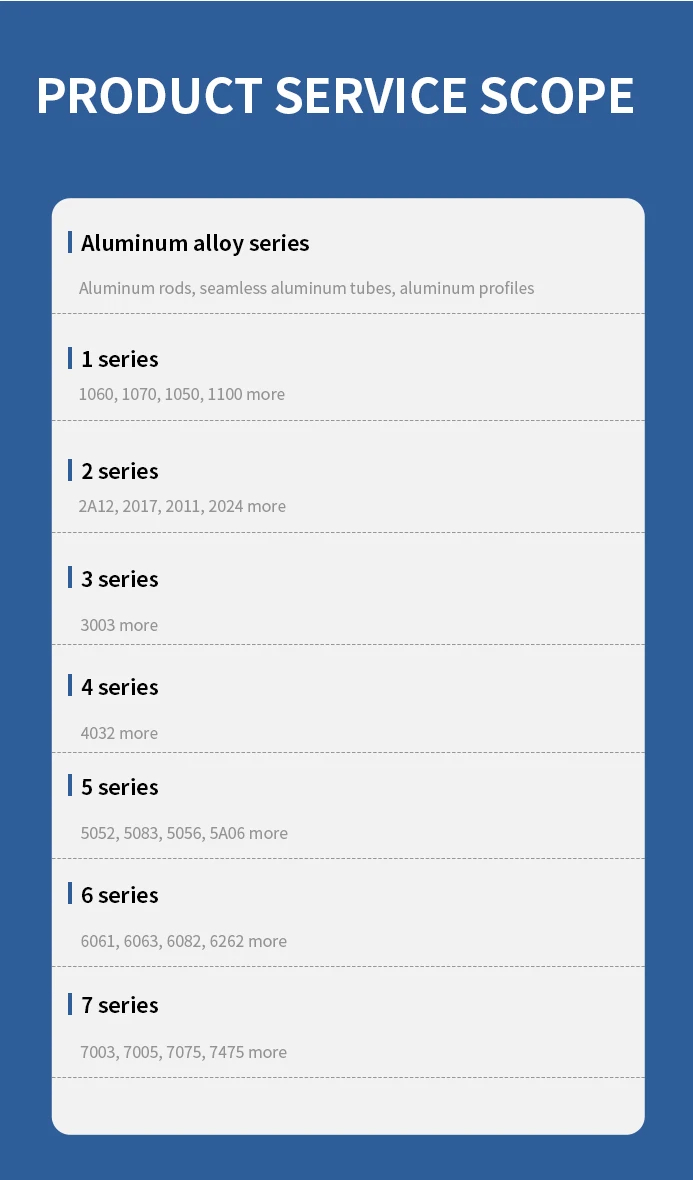

| Aluminum Chemical Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grades | Cu | Si | Fe | Mn | Mg | Zn | Cr | Ti | Pb+Bi | Al | |

| 5052 | ≤0.1 | ≤0.25 | ≤0.4 | ≤0.1 | 2.2-2.8 | ≤0.1 | 0.15-0.35 | ≤0.05 | / | Remainder | |

| 5056 | ≤0.1 | ≤0.3 | ≤0.4 | 0.05-0.2 | 4.5-5.6 | ≤0.1 | 0.05-0.2 | ≤0.15 | / | Remainder | |

| 5754 | ≤0.1 | ≤0.4 | ≤0.4 | ≤0.5 | 2.6-3.6 | ≤0.2 | ≤0.3 | ≤0.15 | / | Remainder | |

| 5083 | ≤0.1 | ≤0.4 | ≤0.4 | 0.4-1.0 | 4.0-4.9 | ≤0.2 | 0.05-0.25 | ≤0.15 | / | Remainder | |

| Aluminum Bar Mechanical Properties | |||||||||||

| Grades | RmMPa | Rp0,2MPa | A50 mm% min. | HBW Typischer Wert | |||||||

| 5052 | ≥170 | ≥70 | ≥15% | ≥47 | |||||||

| 5056 | ≥110 | ≥20 | ≥16% | / | |||||||

| 5754 | ≥180 | ≥70 | ≥13% | ≥47 | |||||||

| 5083 | ≥260 | ≥100 | ≥10% | ≥70 | |||||||

| Aluminum Tube Mechanical Properties | |||||||||||

| Grades | RmMPa | Rp0,2MPa | A50 mm% min. | HBW Typischer Wert | |||||||

| 5052 | ≥170 | ≥65 | ≥17% | ≥47 | |||||||

| 5056 | ≥110 | ≥20 | ≥16% | / | |||||||

| 5754 | ≥180 | ≥70 | ≥13% | ≥47 | |||||||

| 5083 | ≥260 | ≥100 | ≥10% | ≥70 | |||||||

| Spot Regular Status | |||||||||||

| O、F、H111、H112、H12、H22、H32、H14、H24、H34、H18、H28、H38 | |||||||||||

| Spot Routine Implementation Standards | |||||||||||

| Aluminium and aluminium alloys – Chemical compositionand form of wrought productsPart 3: Chemical compositionEnglish version of DIN EN 573-3 | |||||||||||

| Aluminium and aluminium alloys-Cold drawn rod/bar and tube Part 2 Mechanical properties:DIN EN 754-2-2008 | |||||||||||

| Aluminium and aluminium alloys-Extruded rod/bar,tube and profiles Part 2:Mechanical properties:DIN EN_755-2-2008 | |||||||||||

| Aluminium and aluminium alloyextruded rods/bars, round bars Chemical composition+Mechanical properties:ASTM B211M-2001 | |||||||||||

| Aluminium and aluminium alloy extruded rods/bars,tubes and profles Chemicalcomposition+Mechanical properties:ASTM B221 | |||||||||||

| Wrought Aluminium and aluminium alloyextruded profles Chemical composition+Mechanical properties:JIS H4100-2006 | |||||||||||

| Wrought Aluminium and aluminium alloy extruded rods/bars Chemical composition+Mechanical properties:JIS H4040-2006 | |||||||||||

| Aluminium and aluminium alloy extruded rods/bars Chemical composition:GB/T3190-2008 | |||||||||||

| Aluminium and aluminium alloy extruded rods/bars Mechanical properties:GB/T3191-2010 | |||||||||||