In the field of precision manufacturing of optical lenses, the choice of materials is crucial. It not only affects the imaging quality of the lens, but also directly affects the portability, durability and heat dissipation performance of the equipment. Among the many candidate materials, 6063 aluminum alloy has gradually become one of the preferred materials for optical lens manufacturing due to its unique performance advantages. Today, let us follow the footsteps of Zhenhan Alloy and explore in depth why 6063 aluminum can stand out in the field of optical lenses.

1. Ideal choice for lightweight design

First of all, 6063 aluminum alloy is famous for its excellent lightweight and high-strength characteristics. Compared with traditional metal materials such as steel, 6063 aluminum alloy has a lower density, which means that while maintaining the same structural strength, optical lenses made of 6063 aluminum can greatly reduce weight. This is undoubtedly a great blessing for photographic equipment, telescopes, drones and other equipment that pursue portability and load reduction. The lightweight design not only improves the user’s carrying experience, but also helps to improve the endurance of the equipment.

2. Excellent corrosion resistance and aesthetics

Optical lenses often need to be used in various complex environments, including harsh conditions such as humidity, dust or corrosive gases. After surface treatment processes such as anodizing, 6063 aluminum alloy can form a dense and corrosion-resistant oxide film, which effectively resists the erosion of the external environment and prolongs the service life of the lens. At the same time, anodizing can also give aluminum rich colors and luster, enhance the beauty of the product, and meet consumers’ pursuit of high-quality appearance.

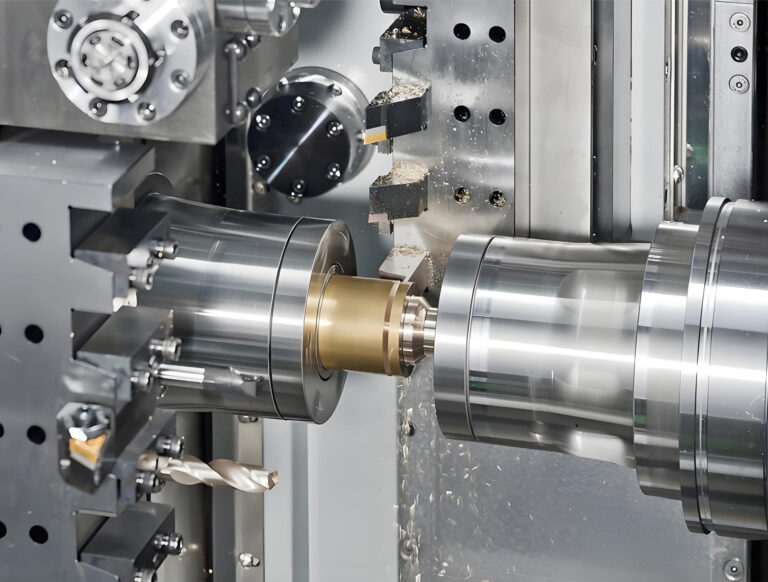

3. Good processing performance and molding ability

The manufacture of optical lenses requires highly precise processing technology, and 6063 aluminum alloy happens to have excellent processing performance and molding ability. Whether it is cutting, drilling, bending or die-casting, 6063 aluminum alloy can show good adaptability, so that the processing accuracy and consistency of lens components are guaranteed. In addition, its good plasticity also makes it more handy when manufacturing complex shapes and fine structures, providing a broad space for the innovative design of optical lenses.

4. Excellent thermal conductivity performance

Under long-term working conditions, optical lenses will generate thermal stress due to the heating of internal components, affecting the image quality. As a high thermal conductivity material, 6063 aluminum alloy can effectively disperse and export the heat generated inside the lens, keep the lens temperature relatively stable, and thus avoid imaging distortion caused by thermal stress. This is of great significance for improving the stability and reliability of the lens in high-intensity use scenarios.

6063 aluminum alloy has become an ideal material in the field of optical lens manufacturing due to its many advantages such as lightweight, corrosion resistance, easy processing, and high thermal conductivity. As a manufacturer focusing on the research and development and manufacturing of high-quality aluminum alloy materials, Zhenhan Alloy continues to promote the application and development of 6063 aluminum alloy in optical lenses and other precision manufacturing fields, bringing more possibilities and surprises to the industry. In the future, with the advancement of science and technology and the continuous innovation of materials, it is believed that 6063 aluminum alloy will continue to play an important role in the field of optical lens manufacturing and help the industry reach new heights.