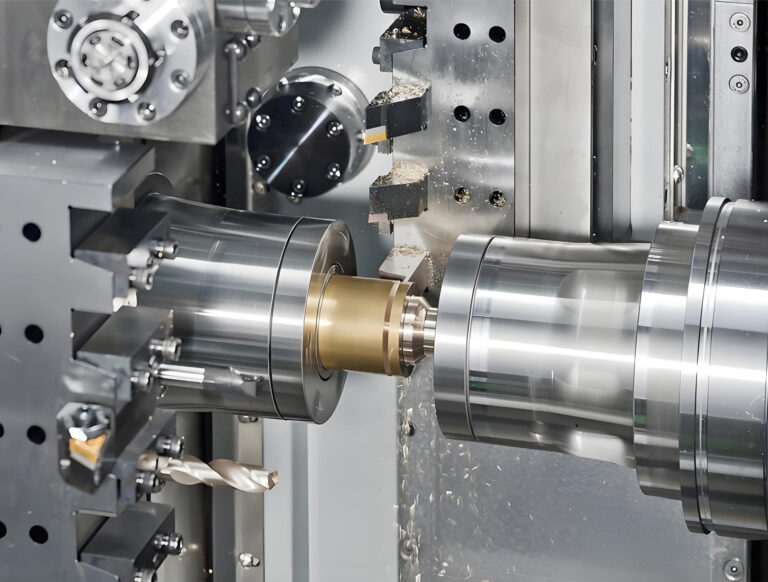

As a common aluminum alloy material, 6061 aluminum bar is widely used in aerospace, automobile manufacturing, electronic equipment and other fields due to its good strength, corrosion resistance and machinability. However, in the CNC (computer numerical control) processing, due to its unique physical and chemical properties, special attention should be paid to the following aspects to ensure processing quality and efficiency.

1. Reasonable selection of cutting parameters

First of all, it is very important to reasonably select cutting parameters. The cutting speed, feed rate and cutting depth should be determined according to the hardness, cutting state and material properties of the 6061 aluminum bar. Since the 6061 aluminum bar is relatively soft, although the cutting speed can be appropriately increased, too fast will lead to increased cutting force, which will cause workpiece deformation and tool wear. Therefore, the cutting speed should be adjusted according to the specific situation, and the feed rate should be controlled to ensure smooth cutting.

2. Optimize cutting tools

The selection and optimization of cutting tools directly affect the processing quality. Since the 6061 aluminum bar has a large plasticity, burrs and built-up edges are easily generated during cutting, so it is necessary to select a tool with a large chip space to reduce cutting deformation. In addition, the number of teeth of the tool should be as small as possible to reduce cutting resistance. The material and geometric parameters of the tool should also be reasonably selected according to the processing requirements to improve the cutting ability and processing efficiency.

3. Control the clamping force

The clamping force is one of the key factors affecting the processing accuracy. When clamping the 6061 aluminum bar, the force should be controlled to be moderate to avoid deformation of the workpiece due to excessive tightening, and at the same time, the workpiece should be stable and not loose. In addition, it is also possible to consider improving the clamping method, using special fixtures or soft claws, etc., to reduce direct pressure on the workpiece and improve processing accuracy.

4. Use suitable cutting emulsifiers

Professional cutting emulsifiers can play a role in cooling, lubricating and cleaning during the processing process, which is particularly important for CNC processing of 6061 aluminum bars. Cutting emulsifiers can effectively reduce cutting temperature and cutting force, reduce tool wear and workpiece deformation, and improve the processing surface quality. Therefore, suitable cutting emulsifiers should be used during the processing, and their concentration and flow rate should be adjusted according to processing requirements.

5. Pay attention to the processing environment

The processing environment is also one of the important factors affecting the processing quality. When CNC processing 6061 aluminum bars, the processing area should be kept clean and dry to avoid the influence of dust and moisture on the processing accuracy. At the same time, it is also necessary to pay attention to controlling the processing temperature to avoid excessive temperature causing thermal deformation of the workpiece.

Guangdong Zhenhan Special Light Alloy Co., Ltd.’s main products include aluminum bars, aluminum tubes, seamless aluminum tubes, aluminum profiles, etc., covering multiple series such as 2 series, 4 series, 5 series, 6 series and 7 series. Zhenhan Alloy has a strong R&D team and advanced technical equipment, and continuously launches new products that meet market demand. At the same time, the company also pays attention to cooperation and exchanges with well-known domestic and foreign companies and scientific research institutions, and continuously improves its technical strength and innovation capabilities. In terms of quality management, Zhenhan Alloy strictly follows the requirements of ISO9001 quality management system for production management to ensure stable and reliable product quality. The company has also established a complete after-sales service system to provide customers with timely and professional technical support and solutions.

CNC processing of 6061 aluminum bars requires attention to the reasonable selection of cutting parameters, optimization of cutting tools, control of clamping force, use of appropriate cutting emulsifiers, and attention to processing environment. As a professional high-end alloy manufacturing plant, Guangdong Zhenhan Special Light Alloy Co., Ltd. has significant advantages and strengths in product quality, technical research and development, and after-sales service.