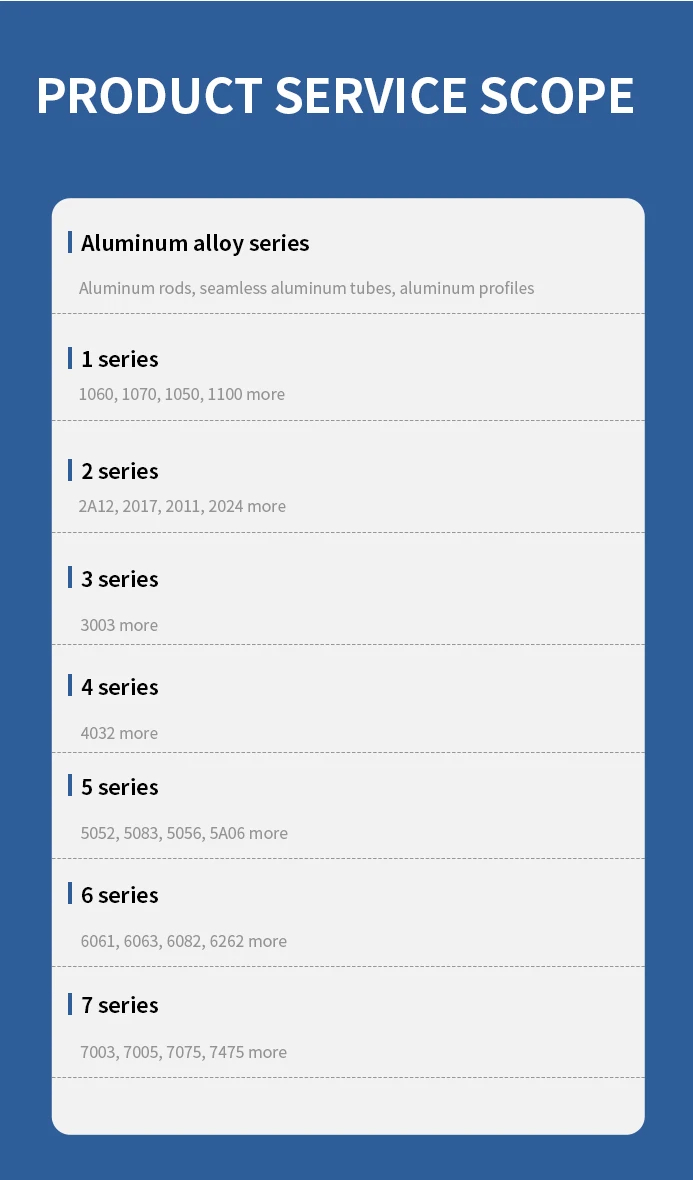

6 series seamless aluminum tube

Brand: 6061, 6063, 6082, 6013, 6262, 6101

Features: It can be strengthened by heat treatment, has medium plasticity in annealing, just quenching and hot state, has good spot welding properties, and has a tendency to form intergranular cracks when using gas welding and argon arc welding, etc.

Applications: aircraft structures (skin, frame, rib beam, bulkhead, etc.), aircraft, ships, transportation, rivets, missile components, truck wheels, propeller components, etc.

Special services: nationwide sales, free samples, free door-to-door delivery, customizable with drawings and samples

Share to:

Product Details

| Aluminum Chemical Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grades | Cu | Si | Fe | Mn | Mg | Zn | Cr | Ti | Pb+Bi | Al | |

| 6061 | 0.15-0.4 | 0.4-0.8 | ≤0.7 | ≤0.15 | 0.8-1.2 | ≤0.26 | 0.04-0.35 | ≤0.15 | / | Remainder | |

| 6063 | ≤0.2 | 0.2-0.6 | ≤0.35 | ≤0.1 | 0.45-0.9 | ≤0.1 | ≤0.1 | ≤0.1 | / | Remainder | |

| 6082 | ≤0.2 | 0.7-1.3 | ≤0.5 | 0.4-1.0 | 0.6-1.2 | ≤0.2 | ≤0.25 | ≤0.1 | / | Remainder | |

| Aluminum Bar Mechanical Properties | |||||||||||

| Grades | RmMPa | Rp0,2MPa | A50 mm% min. | HBW Typischer Wert | |||||||

| 6061 | ≥260 | ≥240 | ≥8% | ≥95 | |||||||

| 6063 | ≥120 | ≥65 | ≥12% | ≥50 | |||||||

| 6082 | ≥205 | ≥110 | ≥12% | ≥70 | |||||||

| Aluminum Tube Mechanical Properties | |||||||||||

| Grades | RmMPa | Rp0,2MPa | A50 mm% min. | HBW Typischer Wert | |||||||

| 6061 | ≥180 | ≥110 | ≥14% | ≥65 | |||||||

| 6063 | ≥120 | ≥65 | ≥12% | ≥50 | |||||||

| 6082 | ≥205 | ≥110 | ≥12% | ≥70 | |||||||

| Spot Regular Status | |||||||||||

| O、F、H111、H112、H12、H22、H32、H14、H24、H34、H18、H28、H38 | |||||||||||

| Spot Routine Implementation Standards | |||||||||||

| Aluminium and aluminium alloys – Chemical compositionand form of wrought productsPart 3: Chemical compositionEnglish version of DIN EN 573-3 | |||||||||||

| Aluminium and aluminium alloys-Cold drawn rod/bar and tube Part 2 Mechanical properties:DIN EN 754-2-2008 | |||||||||||

| Aluminium and aluminium alloys-Extruded rod/bar,tube and profiles Part 2:Mechanical properties:DIN EN_755-2-2008 | |||||||||||

| Aluminium and aluminium alloyextruded rods/bars, round bars Chemical composition+Mechanical properties:ASTM B211M-2001 | |||||||||||

| Aluminium and aluminium alloy extruded rods/bars,tubes and profles Chemicalcomposition+Mechanical properties:ASTM B221 | |||||||||||

| Wrought Aluminium and aluminium alloyextruded profles Chemical composition+Mechanical properties:JIS H4100-2006 | |||||||||||

| Wrought Aluminium and aluminium alloy extruded rods/bars Chemical composition+Mechanical properties:JIS H4040-2006 | |||||||||||

| Aluminium and aluminium alloy extruded rods/bars Chemical composition:GB/T3190-2008 | |||||||||||

| Aluminium and aluminium alloy extruded rods/bars Mechanical properties:GB/T3191-2010 | |||||||||||